The circus comes to town.” Which in the case of the world’s pig producers, means Hannover, Germany. EuroTier is the world’s biggest livestock show. Held biennially in mid-November (11-14 Nov 2014) and organized by the DLG it’s so big buses take visitors round the site to the different halls. In 2012 it attracted 160,000 visitors, with 38,000 of them from abroad. Undoubtedly there will be more foreign visitors this year.

A two day preview event was held in September, which commenced with an update by DLG key personnel. They stated that before the show formally opens there will be an International Pig Event, to be held on Monday Nov. 10, at 1800hrs entitled “Pig farming worldwide” highlighting pig production in Brazil, Russia and China and followed by a networking buffet dinner. At EuroTier itself, in addition to the huge number of exhibitor stands, there are also technical demonstrations and talks on topical issues of the day. The Pig Forum topics this year held in Hall 12 stand/ booth B57 relate to talks on Innovative Piglet Rearing and Tail Biting. In addition in Hall 9 there will be a large display of equipment associated with piglets, in the context of extra welfare considerations.

Companies that are launching new products at EuroTier (for which medals are awarded) apply to attend the Preview in order to talk about their products with members of the German press and a cross section of journalists from all over N. Europe. The event is always oversubscribed and this year just under 90 companies were present, with half being involved in the pig industry. As many ex-pat Brits will be aware, England’s pig industry is notable for having a number of specialist piglet creep feed companies, all of which, ironically, are based in Yorkshire. One of these is A1 Feeds of Thirsk, N. Yorks and they were, sadly, the sole British company present at the preview. A1’s Sales and Marketing Director Daniel Day commented that he had accepted the invitation to attend with some trepidation. “We are exhibiting at EuroTier for the first time and so it seemed logical to expose the company to Europe’s press and get some publicity about our product range. We are well known for our piglet feeds, both in the UK and Denmark but our unique full-fat soya product and concentrate range are not known to the same extent” suggested Mr. Day. After a long day talking to the press, Mr. Day was very well pleased and added that the trip had been well worth the effort. “Furthermore, several excellent contacts had been made which will be followed up at the show in November.”

Big Dutchman is the world’s biggest equipment company and with the company’s HQ being based in Germany regards EuroTier as its “home turf.” Hardly surprisingly the company is launching several new products this year. PRRS is a big problem worldwide and the company is launching a fresh air filter which is used with positive pressure ventilation systems and, significantly, can be retrofitted for existing houses. Tests show that this device filters up to 95 per cent of PRRS viruses, plus other airborne pathogens are also filtered from the air. Another Big Dutchman innovation is its PEF system which makes the entire corn plant i.e. the cob as well as the grain digestible. The system is installed between a pre-mixer and the liquid feeding tank.

Dutch based MS Schippers has grown substantially over the last few years. Hygiene is vital in pig farms and the company has produced its revolutionary Hy-Care housing concept based on technology used in warehouses. The pens are completely separate from the building and can be thoroughly washed down and disinfected. A prototype is already operational with 50 sows having farrowed in the facility.

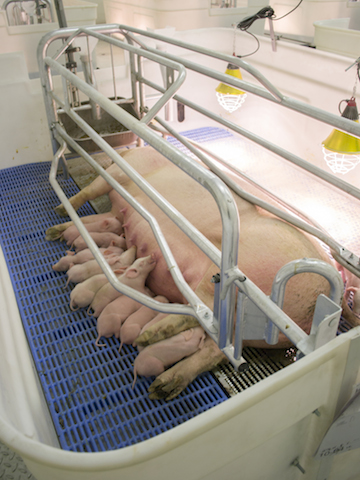

Pig farmers are not stupid and so any equipment in use has evolved over many years. The farrowing crate evolved to reduce pre-weaning crushing but is now perceived by the welfare lobby as being cruel to the sow – is no thought ever given to the piglet that might otherwise have been flattened by a clumsy mum? Consequently we are now seeing a trend back to larger farrowing pens, some with swinging sides/ gates aka farrowing pens circa 1975! In fact the technical display at the 2012 EuroTier featured 12 different free farrowing pens and some of these have been refined and are being submitted for awards at this year’s show. FYI – a modified /updated piece of equipment is considered “new” with regard to entry for an award. ACO Funki previewed three farrowing systems. The Funki Free XL system measures 2.28m x 3.35m and has an opening tubular side, which can be kept closed for the first four to five days after farrowing, to stop overlaying and then opened out once the piglets are stronger and more alert. The Funki Free pen, as the name implies, has no crate at all. Egebjerg International A/S have 15 years’ experience making free farrowing systems and they will be exhibiting their new Welsafe Pen, which allows the sow to farrow freely or enclosed. A big advantage is that it is 2.4m square and as such can be fitted in existing farrowing barns. The creep box can be supplied with a transparent cover plus the design allows for the incorporation of a supplementary milk line. Austrian company Schauer has a lot of experience with farrowing systems and their new CombiBox is able to restrain the sow or allow her to farrow unrestrained.

Infra –red creep lamps are still found in many farrowing barns and a big advantage of a lamp is it’s easy to spot a broken one. ACO Funki feel there is a place for a heat source in the creep lid, radiating downwards. They claim that their new eHeating system lasts up to five years and saves up to 50 per cent in electricity. In addition, it turns itself off after 10days.

We now have a situation in the pig industry whereby sows are now producing huge litters but cannot adequately feed them. The original reason for giving piglets creep feed dates back to times when weaning took place at six to eight weeks. The sow’s milk yield starts to decline after three weeks hence the reason for giving supplementary feed to the piglets. Nowadays it’s well known a heavy piglet at weaning is a heavier pig at slaughter so getting big piglets at weaning is paramount. Given the choice piglets naturally prefer liquids and providing feed via a cup and a milk line is an ideal way to do this. Broring GmbH is one of the largest feed companies in Germany. At the preview they presented their Culina cup system, which will be officially launched in November. According to Broring, other milk lines just deliver milk, whereas the Culina system is designed to deliver a liquid 20 per cent DM pre-starter as the piglets get older, as well as milk. A combination of acids, enzymes and probiotics are included in the milk and pre-starter to prevent digestive upsets.

paramount. Given the choice piglets naturally prefer liquids and providing feed via a cup and a milk line is an ideal way to do this. Broring GmbH is one of the largest feed companies in Germany. At the preview they presented their Culina cup system, which will be officially launched in November. According to Broring, other milk lines just deliver milk, whereas the Culina system is designed to deliver a liquid 20 per cent DM pre-starter as the piglets get older, as well as milk. A combination of acids, enzymes and probiotics are included in the milk and pre-starter to prevent digestive upsets.

paramount. Given the choice piglets naturally prefer liquids and providing feed via a cup and a milk line is an ideal way to do this. Broring GmbH is one of the largest feed companies in Germany. At the preview they presented their Culina cup system, which will be officially launched in November. According to Broring, other milk lines just deliver milk, whereas the Culina system is designed to deliver a liquid 20 per cent DM pre-starter as the piglets get older, as well as milk. A combination of acids, enzymes and probiotics are included in the milk and pre-starter to prevent digestive upsets.

paramount. Given the choice piglets naturally prefer liquids and providing feed via a cup and a milk line is an ideal way to do this. Broring GmbH is one of the largest feed companies in Germany. At the preview they presented their Culina cup system, which will be officially launched in November. According to Broring, other milk lines just deliver milk, whereas the Culina system is designed to deliver a liquid 20 per cent DM pre-starter as the piglets get older, as well as milk. A combination of acids, enzymes and probiotics are included in the milk and pre-starter to prevent digestive upsets.Another way of giving extra liquid feeds to piglets is by means of a mobile feed mixer. Nutrisuin BV is a Dutch company and it is launching its AutoSuin fully automatic mobile feed mixer at the show. The Autosuin mixes up to 40litres of warm fresh feed mix/minute. BabySuin is fed up until weaning, whereas LactoSuin can be fed from days 15 -35 to both suckling and newly weaned piglets.

There were some very interesting new products at the Preview – place your bets as to which gain gold, silver or bronze medals!

Anyone now thinking about attending EuroTier should get cracking as accommodation is at a premium – many exhibitors and visitors find it easier and cheaper to stay in nearby towns and then drive into the show each day. For visitors staying in Hannover, the show site or Messe has excellent tram links with the city centre. •

— By Norman Crabtree

MS Schippers receives the Gold Medal from EuroTier 2014 with

“Hy-Care®”,

Hy-Care®: The best hygiene and perfect care by moveable pens.

The biggest challenges in pig production are to start each round with germ-free pens (HYgiene) and to give optimal care to the animals, without frequently entering the pens (Care). MS Schippers has taken up this challenge with Hy-Care® as result.

Hy-Care® is a revolutionary new housing concept for farrowing sows and weaned piglets in moveable pens. This enables to place the pen always in an optimal environment, both for the animals as the animal care taker. In the Hy-Care® system 5 different rooms are distinguished.

Good care is the base for success in the farrowing period. That is why this farrowing room is designed to make the work for the animal carer as nice and easy as possible, for example because it is easy to reach all animals because there is a work platform along 3 sides of each pen. By focussing on this room, Hy-Care®guarantees a high quality of care during farrowing until piglets are 5 days.

Once the piglets are five days old, the pens are moved to the nursing and piglet rearing rooms where less intensive care is necessary. The animals are checked daily in these rooms, but if work in a pen is necessary, for example for vaccinations, this pen comes to a specially designed workspace area automatically by a rail and lift system. Necessary work can be carried out here. At this workplace the animal carer can walk around the pen, with all tools within reach for an optimal care.

Additionally there is a toilet, where all pens are brought each week to remove all the manure from the pen. Finally there is a washing machine that cleans all pens between rounds resulting in 100% germ free pens.

The Hy-Care® system is characterized by the avoidance of cross-contamination between pens and groups of animals, which leads to a significantly improved state of health, a reduction in the use of medication and optimal production results. •