A large plant is rising out of the ground at Grand Colony near Oakville, and it’s not something anyone would want to eat.

This year, work commenced on doubling the size of the Grand Manufacturing steel fabrication plant, not to increase production, but to make it safer and more efficient.

Concrete footings were poured early in summer for a building that will cover 30,000 square feet over two decks. That almost doubles the size of the plant to 62,000 sq ft.

“We’re so crowded. Right now we are OK, but in wintertime when we’ve got everything crammed in here, the fork lifts crammed in – we have eight forklifts and 20 guys – it’s too crowded,” said shop floor manager Royden Stahl, second in command and son-in-law of plant manager Garry Waldner.

“Two years ago, I started campaigning about getting a bigger shop. You know governments, we have them here, too; you need statistics.”

Stahl’s position was supported by labour board inspectors who stated that, while the plant is still safe, it is crowded and that increases the risk for accidents. It also makes it difficult to reach stored materials and there is no air conditioning in the existing plant, so with the heat generated in the cutters and welders, it gets freakishly hot in there on summer afternoons, said Stahl. On those days, the doors are kept open and work is stopped as the mercury climbs.

Like other colonies, Grand in recent years has shifted operations away from agriculture and turned to manufacturing to shore up its bottom line. Field crops continue, but the dairy quota has been sold. The herd has been reduced to 12 cows and the beef herd is down to 10, enough to supply the colony’s needs.

But the hog operation, like the steel plant, is getting bigger. New feeder rooms are under construction and the farrowing area is being enlarged and upgraded to accommodate loose housing for sows in gestation. New mechanical systems, including automatic dimming lights, will improve comfort for both animals and staff.

In the middle of it all, Grand invested $5.5 million to $6 million in a new kitchen complete with a drive-in basement, brewery, winery, cannery and storage rooms.

The shift toward manufacturing reflects a desire to escape from the cyclic nature of agricultural commodities and invest in business projects that are more stable over the long term, says Stahl.

“We make things because we can,” he said.

Grand Manufacturing was established in 1979, fabricating hog feeders out of three smaller buildings. Eventually, the colony was faced with deciding whether to continue along the same course or upgrade its facilities and expand. The existing building was erected through 2005 and 2006 and some operations are performed off-site at Clearview Colony.

Stahl explains that the three laser cutters can generate enough workflow to keep people busy at both facilities. On the day that Prairie Hog Country visited, one of the lasers had developed a software problem and was under the care of two technicians, one from Winnipeg and the other from Toronto.

Robotics play a large role in relieving some of the manual labour within the plant, such as loading steel into the laser cutters and then pulling the finished pieces and moving them into a deburring machine for finishing. The cutter can be adjusted to .0004 of an inch, about half the size of a human hair, says Stahl. Depending on how it is to be used, each piece can make a number of passes through the deburring machine, coming out a bit shinier each time. If required, it can be brought to a mirror finish.

Steel is brought in from whoever is offering the best deals, including plants in Hamilton, Minneapolis, Brandon and Regina.

Grand still makes the hog feeders for which it was first established, but that component now makes up only about 10 per cent of the workload, says Stahl.

The colony makes field equipment for Mac Don; has a contract with IRONik Design, a Winnipeg-based sign maker marketing its products all over the world, and makes transformer parts for an international hydro-electric company.

And, just for fun, they also use the laser to etch names and designs in the steel mugs that everyone uses for coffee in place of Styrofoam or paper cups.

Excluding one 82-year-old retiree who comes in to work whenever it pleases him, all labour at Grand is sourced from within the colony.

Stahl says he had been working in the farrowing room when he was moved over to the plant.

— continued from page 41

Hiring from within the colony is a challenge, he says.

“Not everybody is a factory worker, and you have to accept that. I was seven years in field and farming and I kind of started sobbing when I got the job here, but after a while you get used to it. Now, you won’t get me out of it.”

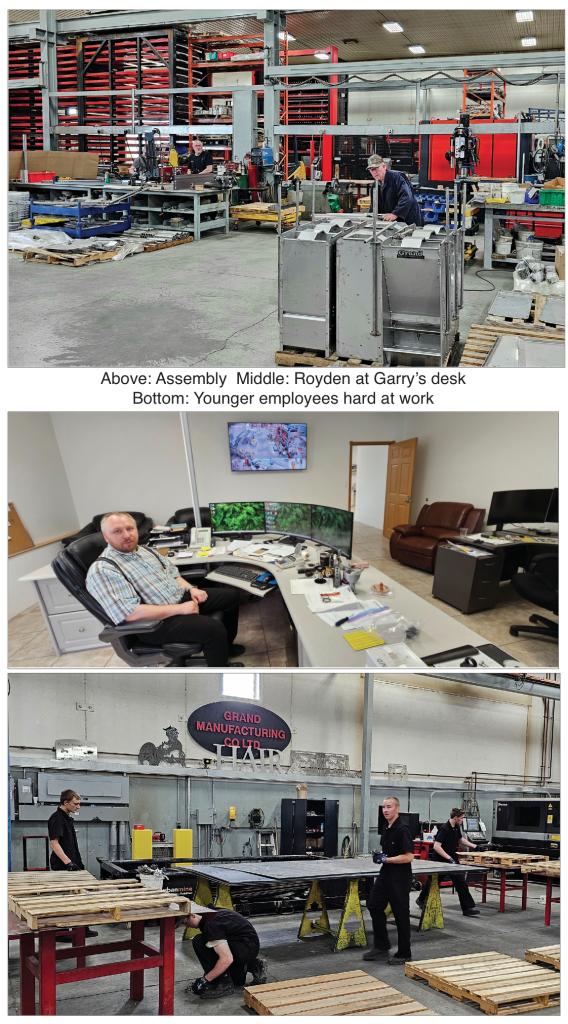

Off the floor and inside an office he shares with his father-in-law, Stahl shows the multi-screen display that they can use to keep eyes on the plant and the computer setups both managers have employed to keep their work in order. Waldner uses three large monitors attached in a partial circle, giving him the space to put up everything he needs to see. The curve means he can look anywhere on any of the screens without changing focus, which can be quite tiring, says Stahl.

Once complete, storage and processes will be organized between the two buildings, with all heat-generating machines to be set up in the air-conditioned area. If that works, they will consider installing A/C in the 2006 side as well.

Stahl says Grand does not want to grow too much, but does want to spread out. The plant is near the limit of what it can do with the number of available workers. If there is a need for more help, they will look to robotics to fill in where they don’t have enough people.

Started in 1959, Grand Colony now has a population of 169 people and could split if the need arises, but there is work for everyone and “we’re still peaceful,” said Stahl.

He regrets that he cannot offer a website for people to make a virtual visit. Their site was hacked by ransomware, which they refused to pay. They lost their server as well as emails. Much of the information contained within the emails was recovered and all the colony’s data were backed up offline, so the only lingering issue is the lack of a functioning website, says Stahl. That will be resolved in time, he says. •

— By Brenda Kossowan