Sunterra’s venture into processing specialized meats for Italian markets has made great strides with help from a powerful partner based in Leduc.

A brochure published by the Alberta Food Processors Association includes comments by Ray Price, president of the Sunterra Group of Companies.

For more than 20 years, says the brochure, Sunterra Farms and Sunterra Meats have relied on the Food Processing Development Centre (FPDC) at Leduc for help bringing new ideas to market.

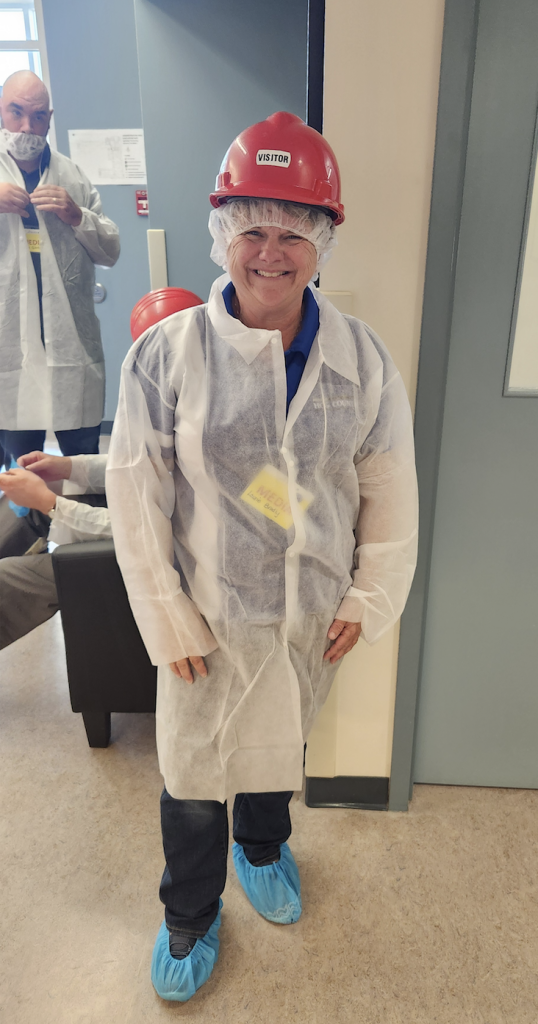

It goes on to state Price had toured the facility and saw an opportunity at the time for his family’s businesses to get help with trials of new products and expanding operations.

On September 26, he made a presentation to an open house held to celebrate the Centre’s 40th anniversary.

“One of the first projects was figuring out how to vacuum-pack bison steaks with food scientist Arie Vandermeer,” says Price in the brochure, published after the tour.

“From the beginning, we forged a strong relationship with the FPDC that has led to more projects almost every year. Their experts have consulted with us on everything from industry regulations to product formulations and to new processes and equipment.”

Studies performed by the Leduc team were integral to Sunterra’s venture in 2016 into a partnership with the Simonini Family of Modena, Italy, creating Soleterra d’Italia. The company now processes fine cured and dried meats at a plant on the Sunterra Farms site near Acme, northeast of Calgary.

It’s website states: “This unique integration of Sunterra’s superior pork and the Simoninis’ trusted Italian recipes make Soleterra d’Italia a name synonymous with quality, and allows us to bring authentic salamis, hams and dry-cured meats to dinner tables across the world.”

Price describes in his presentation how FPDC’s multi-faceted contributions helped Soleterra d’Italia develop a line that has grown from eight to more than 100 meat products marketed around the world.

That included investigations of techniques that prevent spoilage without compromising quality as well as methods for preparing products and improving efficiency.

Licensed under the Canadian Food Inspection Agency’s food safety program, the Centre was established by the provincial government in 1984 as a pilot project to help food and ingredient processors of all sizes develop and market their products.

The 65000-square-foot plant and laboratory now houses more than $20 million in equipment to support innovation from product development through commercialization and marketing.

Flying well below the public radar, its team of researchers and technicians are charged with fostering growth in value-added processing capacity and supporting industry in Alberta.

Please visit www.alberta.ca/food-processing-development-centre for a virtual tour and to learn more about what the FPDC has to offer. •

— By Brenda Kossowan

of the facility.